Exploring the Evolving Landscape of Agitated Nutsche Filter Dryer Manufacturing

December 4, 2023 0 By adminExploring the Evolving Landscape of Agitated Nutsche Filter Dryer Manufacturing: A Journey of Innovation

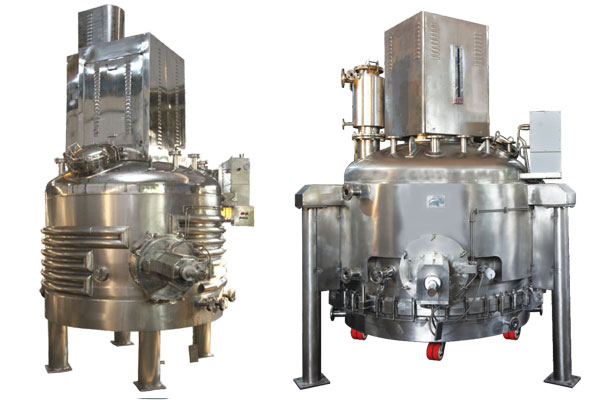

Agitated Nutsche Filter Dryers (ANFDs) have undergone a transformative evolution in manufacturing, driven by technological advancements, industry demands, and a commitment to efficiency. This exploration delves into the changing landscape of ANFD manufacturing, highlighting key trends and innovations shaping the production of this crucial industrial equipment.

1. Precision Engineering and Robotic Manufacturing:

Precision has become the hallmark of ANFD manufacturing. Advances in precision engineering, aided by robotics, have revolutionized the production process. Robotic arms are now employed for intricate tasks, ensuring the consistency and accuracy of critical components such as vessel structures, agitators, and filtration media. This shift towards precision manufacturing enhances the reliability and performance of ANFDs.

2. Materials Innovation for Enhanced Durability:

Material science is playing a pivotal role in the evolution of ANFD manufacturing. The industry is witnessing a surge in the use of advanced alloys and coatings that offer superior corrosion resistance and durability. These materials are carefully selected to withstand the harsh conditions of chemical processes, extending the lifespan of ANFDs and broadening their application range.

3. 3D Printing in Prototyping and Customization:

The adoption of 3D printing technology has streamlined the prototyping and customization phases in ANFD manufacturing. This innovative approach allows for rapid prototyping of components, facilitating quicker design iterations and reducing time-to-market. Manufacturers can now customize ANFDs for specific applications, meeting the diverse needs of industries with greater flexibility.

4. Smart Manufacturing and Industry 4.0 Integration:

Smart manufacturing principles and Industry 4.0 technologies have permeated ANFD production. Sensor integration, real-time monitoring, and connectivity features are becoming standard in modern ANFDs. This shift towards smart manufacturing not only enhances operational efficiency but also enables predictive maintenance, minimizing downtime and optimizing the lifespan of the equipment.

5. Sustainable Manufacturing Practices:

The demand for sustainability has influenced ANFD manufacturing agitated nutsche filter dryer processes. Manufacturers are increasingly adopting eco-friendly practices, focusing on energy-efficient designs and the use of recyclable materials. Sustainable manufacturing not only aligns with global environmental goals but also resonates with industries committed to reducing their carbon footprint.

6. Integration of Automated Process Control Systems:

Automated process control systems are becoming integral to ANFD manufacturing. These systems leverage advanced algorithms and sensor technologies to regulate key parameters such as temperature, pressure, and agitation speed. The integration of automation not only ensures consistent product quality but also streamlines the manufacturing process, reducing the margin for error.

7. Training and Skill Development for Operators:

As ANFDs become more advanced, the need for skilled operators has become paramount. Manufacturers are investing in training programs to equip operators with the expertise required to handle the intricacies of modern ANFDs. This focus on skill development contributes to safe and efficient operation, optimizing the performance of ANFDs on the shop floor.

The Road Ahead:

The evolving landscape of ANFD manufacturing is characterized by a convergence of precision engineering, materials innovation, smart technologies, and sustainability. As the industry continues to embrace advancements, ANFDs are poised to play an increasingly pivotal role in facilitating efficient and reliable solid-liquid separation and drying processes across diverse sectors. The journey of innovation in ANFD manufacturing reflects a commitment to pushing the boundaries of what is possible in industrial processing.